Honest efforts, ongoing commitment, strengthening ecosystems and industry ethics

Join the "JUST GET ONBOARD" movement and embrace sustainable, high-quality alternatives like GaiaTone and Sonowood for the future of music. Discover the journey of wood from forest to product and the importance of responsible forestry by exploring the story behind the FSC label.

VIOLIN FINGERBOARDS & MORE…

PRESENTING THE BEST SUSTAINABLE EBONY ALTERNATIVES

Choose the ebony alternative that suits your needs and preferences.

"JUST GET ONBOARD" — is a movement. GaiaTone and Sonowood are alternatives to traditional Ebony fingerboard materials, with a focus on sustainability. The title plays on the idea of getting "on board" with the future of music—a movement that champions both environmental responsibility and uncompromising musical excellence.

"JUST GET ONBOARD" encourages musicians, and music enthusiasts to take part in this pivotal shift toward ebony alternatives. The campaign’s message is simple: by choosing GaiaTone and Sonowood, you're choosing to make a positive impact on the planet without sacrificing the rich, authentic sound you love. It speaks directly to those who want to be a part of the change, be it through their environmental values or by seeking a higher quality playing experience.

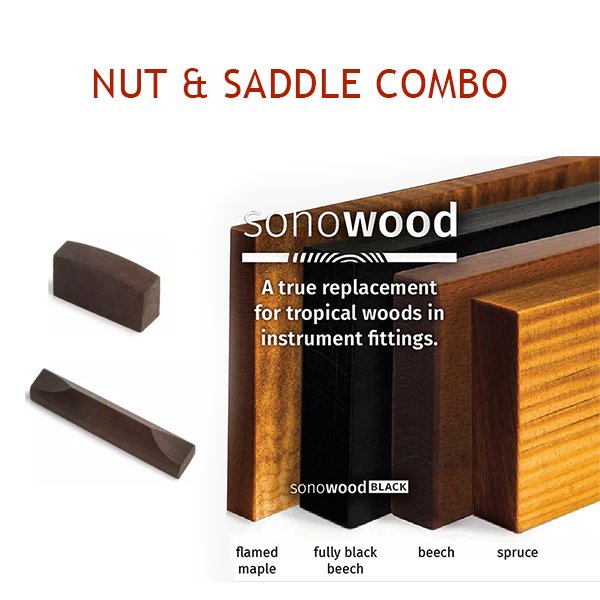

| Why Choose Sonowood | Why Choose GaiaTone | Sonowood replicates the look and feel of natural wood, providing luthiers with an authentic and traditional appearance. | GaiaTone is a sustainable option, minimizing environmental impact while offering a pre-fit solution for efficient crafting. |

|---|---|

| Sonowood is an environmentally friendly choice, contributing to conservation efforts by avoiding the use of natural ebony. | GaiaTone strikes a balance between sustainability and affordability, making it a practical choice for luthiers on a budget |

For inquiries within Europe, please contact our dedicated partner, Claudia Klein. She's happy to help with any questions you may have. Her contact information is listed below.

Contact: Claudia Klein

email: willkommen@communique-pr.de

Phone: +49 871 1423 1064

FAQ’s FOR CARBIDE BLADES

-

Carbide is super tough, but its edges can be a bit rougher than a finely honed steel blade.

-

Carbide blades are like the workhorses. Use them when you need to cut tough stuff like: Super-hard woods, Things that wear down blades quickly, like fiberboard. Carbide stays sharper for much longer than steel, so it's great for big projects.

-

Yes! Carbide is valuable. Don't just throw it away. Many metal recycling places or industrial tool suppliers will take your old carbide. The materials in carbide can be used to make new tools.

-

It's tricky. Carbide is so hard that you need special tools (like diamond stones) to sharpen it. Sometimes, it's cheaper to just replace the insert than to sharpen it.

-

Think of it like replaceable razor blades. Carbide is expensive! Small inserts are cheaper to make than a whole blade. When the insert gets dull, you just pop in a new one instead of replacing the whole thing. The insert is held securely in a strong blade holder for tough jobs.

-

Advantages:

Toughness: Carbide blades are incredibly strong and can handle tough jobs that would break a steel blade.

Long-lasting: They stay sharp much longer than steel blades, saving you time and money on sharpening or replacing them.

Precision: Carbide can be formed into very precise shapes, making them great for fine cuts.

Disadvantages:

Cost: Carbide blades are more expensive upfront.

Brittleness: While tough, carbide can be more brittle than steel, meaning it can chip or break if you drop it or use it incorrectly.

Sharpening: Sharpening carbide requires special tools and expertise.

-

Visible damage: Any chips or cracks mean it's time for a new one.

Poor performance: If it's not cutting cleanly, burning the material, or making strange noises, it's probably dull.

Effort: If you find yourself pushing harder than usual to make a cut, the blade may be worn out.

-

Simple is best: Often, wiping it down with a cloth and some soapy water is enough.

Tougher messes: For stubborn buildup, you can use a specialized carbide cleaner.

Avoid harsh chemicals: Strong solvents can damage the blade or its coating.

-

Protective case: A dedicated case keeps the blades from bumping into each other and getting chipped.

Dry place: Moisture can cause rust or corrosion, even on carbide.

Away from children: Sharp blades should always be stored out of reach.

-

Forcing the cut: Let the blade do the work. Forcing it can cause damage.

The aperture – how much material we try to remove at a time probably is – slow, thin removal of material rather than large chunks.

-

Materials: The materials used to make carbide are more expensive than those used for steel.

Manufacturing: The process of making carbide is more complex and requires specialized equipment.

Durability: You're paying for a blade that will last much longer than a steel blade.

-

It depends on how you use it! But generally, a carbide blade can last 10 to 25 times longer than a comparable steel blade.

-

Often, yes! If you're doing a lot of cutting, working with tough materials, or need very precise cuts, the longer lifespan and better performance of carbide can make it a worthwhile investment.

PLANE BLADE HOLDERS AND INSERTS

First-time buyers, please purchase both the plane holders and inserts.

We provide custom carbide inserts and stainless steel holders to make your planes super-hard and super durable! Reducing the need for re-sharpening, these carbide inserts make planing any material, including GaiaTone, a breeze reducing wear and tear on your blades. The insert comes in two parts: an adaptor for the plane, and replaceable blades that can be switched as they dull with minimal expense. Each blade attachment can be flipped for double life! We designed these inserts for use with our GaiaTone material which is very hard, but they are great for all purposes: ebony, Sonowood, GaiaTone, and many other workshop applications. Currently, we have models available for select Lie Nielsen and Veritas planes but we are working to create similar adapters for many more models!

Now Available: Carbide insert resharpening service. Resharpen your carbide inserts for half the cost, extending the life of your cutting tools. Send us your blades, and we'll do the rest.

SHOP - SONOWOOD / GAIATONE

FINGERBOARDS

Ensure to include the complete set, including tailpieces, nuts, saddles, packages, and frog blanks.

TAILPIECES AND NUT & SADDLE

PACKAGES

BLANKS

Enhancing Your Violin's Sound and Playability: The Importance of a High-Quality Fingerboard

The fingerboard is an essential component of any violin. It's the long, narrow strip of wood that runs down the length of the instrument's neck and is where the strings are pressed down to create different notes. A well-crafted fingerboard can significantly enhance the sound and playability of a violin.

When it comes to selecting a fingerboard, there are several factors to consider. The type of wood used is critical as it can affect the violin's tone and responsiveness. The most commonly used woods are ebony, rosewood, and boxwood, with ebony being the preferred choice due to its density and durability. Sonowood and GaiaTone have properties similar to Ebony, making them the ideal substitutes.

The curvature of the fingerboard is another crucial factor. A properly curved fingerboard allows for smooth, precise finger movements, making it easier to play difficult pieces. The angle and height of the fingerboard also affect the sound and playability of the instrument, so it's crucial to choose a fingerboard that is perfectly aligned with the instrument's bridge.

In addition to the wood and curvature, the fingerboard's finish can also impact the violin's sound and feel. A smooth, polished finish can make it easier to slide fingers up and down the fingerboard, while a rough or sticky finish can make it more challenging to play certain passages.

When selecting a fingerboard, it's essential to work with a skilled luthier who can help you choose the right wood and curvature for your instrument. By selecting a high-quality fingerboard that's properly aligned and finished, you can significantly enhance the sound and playability of your violin.